Vortex spinning is one of the automatic, continuous, high-speed and high-yield spinning methods. It is an advanced spinning technology in the world today. It has good yarn quality, short production process, less labor, less energy consumption, less land occupation and less investment. , The production cost is low and high.

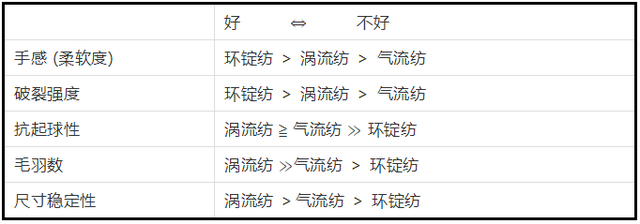

Comparison of vortex spinning and other spinning methods

01

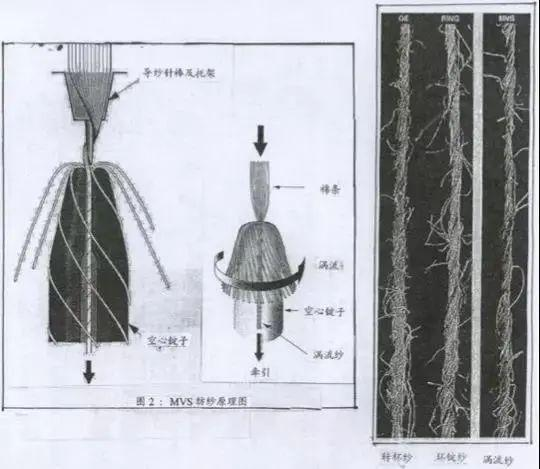

Principle of Yarn Formation

The vortex spinning machine includes drafting, vortex twisting, hollow spindle, yarn forming, winding and other parts.

After the whisker output by the front roller enters the nozzle, it moves at a high speed along the spiral surface at the entrance. The fiber head end of the whisker enters the hollow tube at a higher speed, while the tail end is dumped on the cone surface of the outer wall of the hollow tube. The output of the yarn sliver is gradually twisted into yarn under the action of the vortex, and then output from the hollow tube, and then wound into a cone yarn. This is the yarn forming process of vortex spinning.

02

Advantages of vortex spinning

Compared with other new types of spinning, vortex spinning has the following advantages.

High spinning speed and high output

Vortex spinning applies the principle of aerodynamics and uses a vortex tube to form yarn. The twisting efficiency of the vortex to the yarn is much higher than that of mechanical twisting.

Take spinning 30s viscose yarn as an example, the spinning speed is 400~450m/min spindle (ring spinning 17m/min spindle, Swiss air spinning 128m/min spindle).

Strong adaptability, suitable for making pile products

The structure of the vortex yarn is relatively bulky, so its dyeability, slurry absorption and air permeability are better, and the yarn has better pilling resistance and abrasion resistance. The yarn count range is limited to medium and low count yarns, which is suitable for pile products.

The shortest production process and the highest product manufacturing rate

Vortex spinning is directly spun from fiber sliver into cheese yarn, so like other new types of spinning, the two processes of roving and winding can be omitted. Due to the low end breakage rate of vortex spinning, the loss of back-spatter is small, and the finished rate is as high as 99%.

Automatically remove yarn defects

The entire spinning process is monitored by an electronic system, and when a yarn defect is found, it is automatically removed. The entire spinning process is fully automatic and continuous. If a problematic spindle is found, it can automatically stop spinning for a single spindle.

Simple operation and convenient connection

Vortex spinning adopts a vortex tube to form yarn. Because the vortex tube is stationary and has no high-speed rotating parts, the joint is very convenient and simple, and there is no need to clean after the end is broken, which improves the working environment. There are no special requirements for spinning equipment and temperature and humidity. Because the vortex spinning has no high-speed rotating parts, there is no high-speed bearing lubrication problem, low loss, low noise, and convenient maintenance.

03

Yarn structure and characteristics

The vortex yarn is a dual structure yarn with core fiber and outer fiber. The core fiber of the yarn is arranged in parallel without twisting. The outer fiber is wrapped in a regular spiral on the surface of the yarn core. This is due to its unique yarn forming principle.

The outer layer of the vortex yarn has a large proportion of regular spirally wrapped fibers, accounting for about 60% of the total number of fibers, so that the inner untwisted fibers are almost completely covered, which overcomes the core exposure problem of the air-jet yarn, and the surface fiber arrangement is more similar to the traditional Ring-spun yarn has a tighter structure.

04

Yarn characteristics

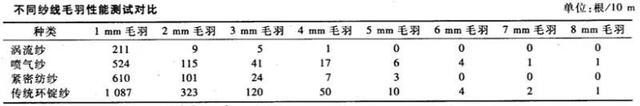

Less hairiness

Because the vortex yarn is a double structure yarn composed of wrapping fibers and new fibers, the outer fibers are regularly spirally wrapped tightly on the surface of the new fibers. Because of its unique yarn structure, the fiber ends and ends are twisted into the yarn. In the thread, so the vortex yarn has less hairiness.

The surface of the yarn is more stable, and the hairiness increase of post-processing is significantly lower than that of other yarns.

Not easy to fluff and pilling

Because the yarn has less hairiness, the vortex yarn is not easy to fuzz and pilling, but because it has fewer short hairiness, it feels slightly harder than other yarns.

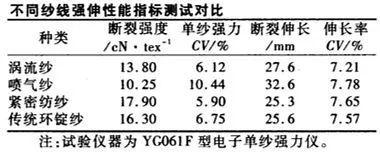

The single yarn strength of vortex spinning is low

Good wear resistance

The breaking strength of single vortex yarn is lower than that of compact spinning and traditional ring-spun yarn, but higher than that of air-jet yarn, and the single yarn has lower strength unevenness, and its breaking elongation is lower than that of air-jet yarn, but it is lower than that of traditional ring-spun yarn and compact spinning. The yarn is high and the unevenness of elongation at break is the best.

Good wear resistance

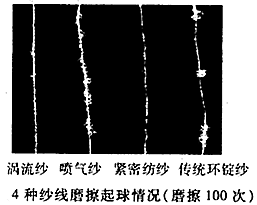

Both vortex yarn and air-jet yarn are composed of core fiber and outer fiber. The surface of the yarn core is wrapped with fiber. The yarn is not easy to produce relative slippage, so it has high wear resistance.

The wear resistance of vortex yarn is better than that of air-jet yarn because the outer fiber is regularly spirally wrapped, and the proportion of the outer fiber is so large that the inner untwisted fiber is almost completely covered.

Service Hotline

+86-15113166056